Nothing Comes Close To An

Arctic Sectional

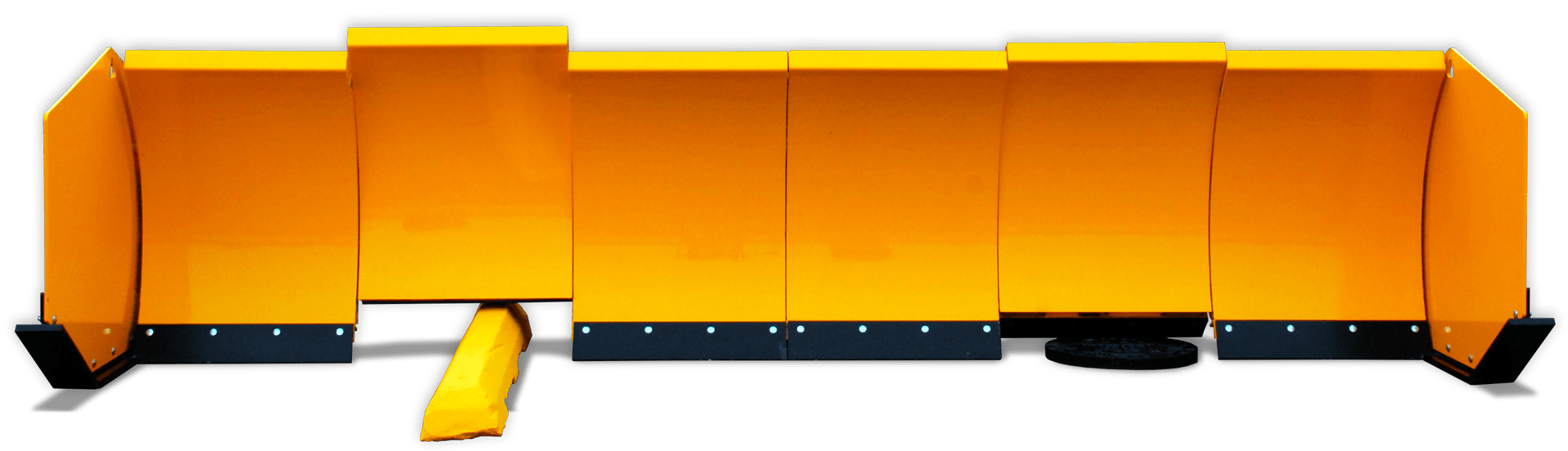

Time after time, no other plow clears a parking lot like the Sectional Sno-Pusher™ from Arctic®. Our unique sectional design allows the plow to follow the contour of the surface grade, clearing down to the pavement on the first pass, while at the same time protecting your lot, your equipment, and your operator. See what sets Arctic’s Sectional Sno-Pusher™ apart. —

Sectional Sno-PusherTM

Features

The Only Pusher You'll Ever Need.

Sectional Sno-PusherTM

Specifications

-

Compact Duty Models

24" Wide MoldboardsModel Width Height Depth Weight CD-6.5 78.5" 26" 50" 974 lbs CD-8.5 102.5" 26" 50" 1,025 lbs ModelCD-6.5Width78.5"Height26"Depth50"Weight974 lbsModelCD-8.5Width102.5"Height26"Depth50"Weight1,025 lbs -

Light Duty Models

30" Wide MoldboardsModel Width Height Depth Weight LD-8 96" 32" 58" 1,150 lbs LD-10.5 126" 32" 58" 1,792 lbs LD-13 156" 32" 58" 2,050 lbs LD-15.5 186" 32" 58" 2,456 lbs ModelLD-8Width96"Height32"Depth58"Weight1,150 lbsModelLD-10.5Width126"Height32"Depth58"Weight1,792 lbsModelLD-13Width156"Height32"Depth58"Weight2,050 lbsModelLD-15.5Width186"Height32"Depth58"Weight2,456 lbs -

Heavy Duty Models

32" Wide MoldboardsModel Width Height Depth Weight HD-11.5 137.5" 47" 73" 3,190 lbs HD-14 169.5" 47" 73" 3,592 lbs HD-17 201.5" 47" 73" 4,004 lbs HD-19.5 233.5" 47" 73" 4,468 lbs HD-22 265" 47" 73" 4,878 lbs HD-27.5 329.5" 47" 73" 5,288 lbs ModelHD-11.5Width137.5"Height47"Depth73"Weight3,190 lbsModelHD-14Width169.5"Height47"Depth73"Weight3,592 lbsModelHD-17Width201.5"Height47"Depth73"Weight4,004 lbsModelHD-19.5Width233.5"Height47"Depth73"Weight4,468 lbsModelHD-22Width265"Height47"Depth73"Weight4,878 lbsModelHD-27.5Width329.5"Height47"Depth73"Weight5,288 lbs

Dealer Locator

Product Support

Equipment Matcher